- Non-contact level measurement of liquids

- Applicable for continuous level measurement of liquids

with slightly aggressiveness in storage containers, reactors or process vessels. - Measuring ranges : 0 ~ 30m

- Accuracy : ± 2mm

- Process pressure : -1 bar ~ 2 bar

- Process temperature : -40℃ ~ +200℃

- Media-conracting materials :

Process fittings: 316L

Antenna: PEEK PTFE

Seal: FKM, EPDM, KALREZ - Display and Adjustment LCD display, tank side display and tank side hub

- Communications : HART, RS485 Modbus, 4-20 mA...

- Protect Level : IP67

- Ex information : EX ia IIC T6 Ga Ex d ia [iaGa] IIC T6/T2 Gb

- Different Models depending on the application

- Non-contact level measurement of liquids

- Continuous level measurement of aggressive liquids

(storage containers, reactors or process vessels...) - Measuring ranges : 0 ~ 20m or 0 ~ 30m

- Accuracy : ± 2mm

- Process pressure : -1 bar ~ 2 bar

- Process temperature : -40℃ ~ +200℃

- Media-conracting materials :

Process fittings: PP

Antenna: PP

Seal: FKM, EPDM, KALREZ - Display and Adjustment LCD display, tank side display and tank side hub

- Communications : HART, RS485 Modbus, 4-20 mA...

- Protect Level : IP67

- Ex information : EX ia IIC T6 Ga Ex d ia [iaGa] IIC T6/T2 Gb

- Different Models depending on the application

- Non-contact level measurement of liquids

- Applicable for continuous level measurement of liquids aggressive liquids

with lower demands on pressure and temperature ranges. - Measuring ranges : 0 ~ 30m

- Accuracy : ± 2mm

- Process pressure : -1 bar ~ 2 bar

- Process temperature : -40℃ ~ +130℃

- Media-conracting materials :

Process fittings: PP

Antenna: PP

Seal: PP PTFE - Display and Adjustment LCD display, tank side display and tank side hub

- Communications : HART, RS485 Modbus, 4-20 mA...

- Protect Level : IP67

- Ex information : EX ia IIC T6 Ga Ex d ia [iaGa] IIC T6/T2 Gb

- Different Models depending on the application

- Non-contact level measurement of liquids

- Applicable for continuous level measurement of liquids

extremely aggressiveness in storage containers, reactors or process vessels. - Measuring ranges : 0 ~ 30m

- Accuracy : ± 2mm

- Process pressure : -1 bar ~ 16 bar

- Process temperature : -40℃ ~ +200℃

- Media-conracting materials :

Process fittings: 316L

Antenna: PTFE, PFA, PP

Seal: FKM, EPDM, KALREZ - Display and Adjustment LCD display, tank side display and tank side hub

- Communications : HART, RS485 Modbus, 4-20 mA...

- Protect Level : IP67

- Ex information : EX ia IIC T6 Ga Ex d ia [iaGa] IIC T6/T2 Gb Ex iaD tD A21 IP67T80ºC/T290ºC

- Different Models depending on the application

- High measurement accuracy: Accuracy: 0.5%

- Wide measuring range: DN15 to DN6000

- Energy meter: Measurement of thermal and cooling energy

- Wide temperature range: Fluid from -30 ° C to 160 ° C

- Multiple communication interface as standard:

- Outputs: RS-485 Modbus RTU ~ 1x 4-20 mA ~ 1x Pulse ~ 1x Relay

- Inputs: 3x 4-20mA (acquisition of temperature, pressure, level signals, etc.)

- Multiple materials and pressures available:

- Carbon steel, 304 stainless steel, 316 stainless steel, 1.0 Mpa, 1.6 Mpa, 2.5 Mpa

- IP68 protection - Fully waterproof: Does not fear splashing water or humid environments

- Waterproof keyboard: 4 keys - settings and multiple functions

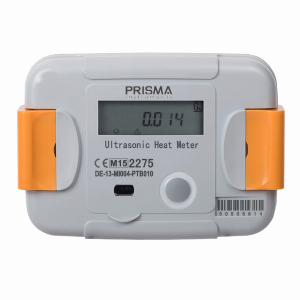

- Thermal & cooling energy Advanced technology & electronics

- Easy to install & use

- Accuracy, stability & longevity

- Communications & remote reading

- Compact & robust design

- Vertical or horizontal mounting

- Multifunctional display/ 8 digit LCD screen

- Long life battery or power supply

- Suitable for lower water quality

- 4 ~ 20mA 2 inputs (fully isolated) HART

- Power supply: 7-30Vdc

- IP67

- Transmitter material: PVDF

- Internal temperature compensation

- Beam angle: 7

- Unaffected by liquid temperature or viscosity

- Maximum measurement: 12m

- Measuring range: Liquid (0.25 ~ 4) m

- Process connection: G1½A

- PTFE 、 PU / PC

- Process temperature: (-40 ~ 70) ° C

- Process pressure: (-0.02 ~ 0.1) MPa

- Output signal: (4 ~ 20) mA / HART

- Power: dual-wire (DC24V) four-wire (DC24V / AC220V)

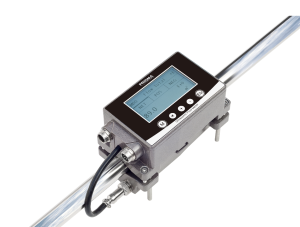

For all clear, non biphasic liquids and all types of pipes from DN20 to DN 1200 :

- Measurement accuracy 1% F.S

- Communications : 4~20 mA & RS485 Modbus

- Programmable data logger 16 GB SD card

- Battery 16 hours autonomy

- Non-invasive transducers Stainless steel IP68

- Mounting rails for optimal measurement

- Energy metering included

- 2x TT02 IP68 transducers

- -40 °C ~ 80 °C (130°C optional)

- Suitable for pipes DN 20 mm to DN 1200 mm

- Mounting rails with strip and clamps

- Standard cable length: 5 meters

- 2x non-intrusive PT100 IP68 temperature sensors

- Measurement of thermal & cooling energy

€3,000.00

Price

- Measuring range: Liquid (0.4 ~ 8) m

- Process connection: G2A

- PTFE 、 PU / PC

- Process temperature: (-40 ~ 70) ° C

- Process pressure: (-0.02 ~ 0.1) MPa

- Output signal: (4 ~ 20) mA / HART

- Power: dual-wire (DC24V) four-wire (DC24V / AC220V)

- Measuring range: Liquid (0.5 ~ 15) m

- Process connection: Flange or swivelling holder

- PTFE 、 PU / PC

- Process temperature: (-40 ~ 70) ° C

- Process pressure: (-0.02 ~ 0.1) MPa

- Output signal: (4 ~ 20) mA / HART

- Power: dual-wire (DC24V) four-wire (DC24V / AC220V)

- Hose material: Metal/ Rigid plastic tube made of PCV, PP or PVDF

- Liquid type: Water/Other (fluids without solid particles or impurities)

- 0-75° (no surface freezing)

- Low speed cut-off value: 0.1m/s

- Display: 256*128, LCD

- Response time: 0.5-60s

- Accuracy: +/-2%, (+/-1% after calibration)

- Data storage period: 300ms

- Memory for data saving: EEPROM, data storage more than 10 years

- I/O power supply: M12 type aviation plug

- Output: 4-20mA

- Communication: Modbus RS485

- Option for output: OCT, alarm relay

- Power supply: 10-24VVDC

- Electrical power : <3W

- Ambient temperature : -10° to 60°C

- Cable length: 2m, PT100 sensor cable length is 9m